Product Details

|

Product Name |

Brake pads |

|

Size |

Standard |

|

Material |

Steel |

|

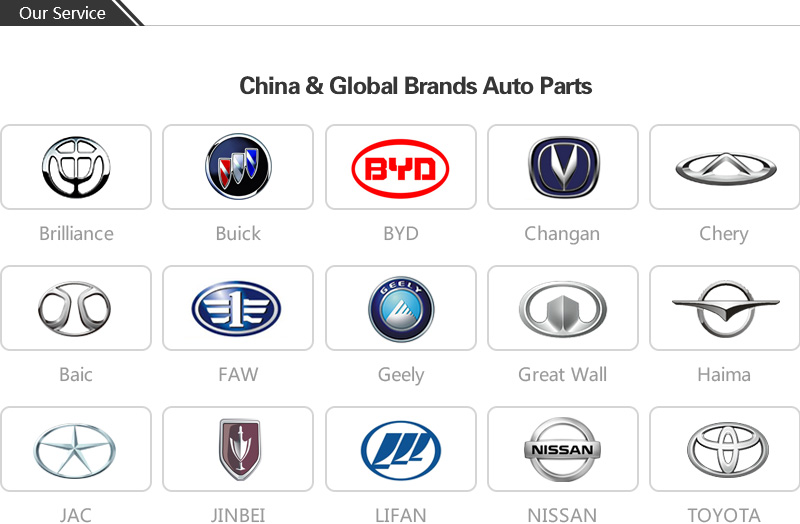

Car Application |

Chery B14 |

|

Place of Origin |

China |

|

Delivery Port |

Dalian |

|

Certification |

ISO9001/TS16949 |

|

Max. Production Capacity |

10000Piece/Pieces per Month |

|

Samples |

Charge |

1. Standard Exporting package

2. Original package or neutral package

3. According to clients ' needs

4. Shipped in10-35 days after payment

A. SASO for K.S.A

B. CIQ for Egypt, Ethiopia

C. COO, certified CI for Egypt, Argentina

D. Form A for European countries

E. Form E for Malaysia

F. Form F for Chile

G. COC for Algeria, Kenya, Bangladesh, Hatti, Nigeria

Two aluminum metal matrix composites (MMC) reinforced with 13 vol.% of SiC or B4C particles were made by stir casting followed by hot extrusion. Effects of sliding velocity on the wear, friction and tribochemistry of the worn surfaces of both composites sliding against a commercial phenolic brake pad have been investigated under dry condition. The wear tests were carried out using a pin-on-disc type apparatus at two linear sliding speeds: 1.62 and 4.17 m s−1 under a constant contact pressure of 0.75 MPa for a sliding distance of 5832 m. The coefficient of friction was recorded and wear rate of the MMC pins calculated from mass loss measurement. Scanning electron microscope (SEM) equipped with energy dispersive X-ray spectroscopy (EDX) was used to investigated the worn surface. It is observed that higher sliding velocity leads to lower wear rate and lower friction coefficient for both MMCs. Formation of a compact transfer layer has been identified in the matrix region of the worn surface of the MMCs. The transfer layer mostly consists of constituents of the phenolic pad material which acted as counterbody. The amount of the constituents of the counterbody in the transfer layer is seen to increase as sliding velocity increases. It is suggested that the transfer layer on MMC acts as a protective cover and helps reduce both wear rate and friction coefficient.

As one of the leading manufacturers and suppliers in China, our distributors spread around the world. Please be free to wholesale the chery brake pads front b14-6gn3501080ba for chery b14 cross eastar v5 from our factory. Fast delivery and good after-sale service are available.

Inquiry

Related Products